The ground underlying a structure is as crucial to geotechnical engineering and construction as the structure itself. Before a single brick is laid or a tunnel is bored, engineers must first understand the condition of the subsurface. Whether a structure lasts for decades or crumbles suddenly depends on what’s behind it.

One of the key tools used to assess the integrity and quality of underground rock is RQD, or Rock Quality Designation. Developed to provide a standardized way of evaluating rock masses, RQD has become an essential parameter in soil investigations, foundation design, tunneling, slope stability analysis, and more.

This comprehensive guide will explain in details what is RQD in soil investigation, including practical examples in Malaysia.

What is RQD in Soil Investigation?

RQD was introduced in 1964 by D.U. Deere, an American engineer who aimed to provide a standardized way to assess the integrity of rock masses.

Rock Quality Designation, or RQD, is a measurement used in geotechnical engineering to describe the quality of rock core samples retrieved from the ground.

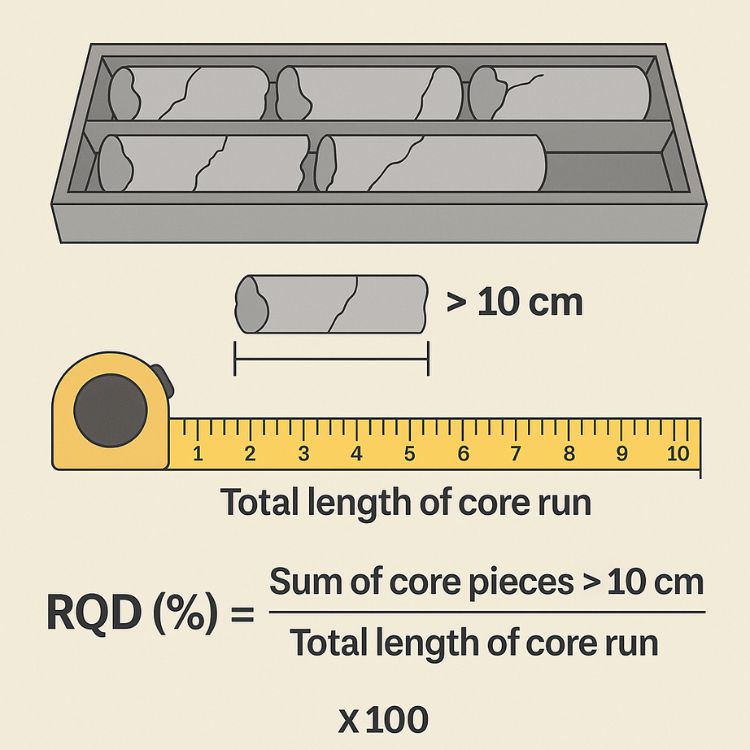

RQD measures the percentage of intact rock pieces that are longer than 10 centimeters obtained from a core sample. The core is usually extracted using a diamond core drill, and then the solid, unbroken sections of the core that exceed 10 cm in length are measured.

How to Calculated RQD in Soil Investigation?

RQD are calculated using the following formula:

RQD = [ Sum of the core pieces > 100 mm ] / [ Total Core Length ] x 100

For example, if a one-meter core sample contains 70 cm worth of rock pieces longer than 10 cm, the RQD would be 70%. This indicates that 70% of the core is solid, while the rest is likely fractured or broken.

The values of RQD are then classified into categories, each indicating a different level of rock quality depends on it scores:

- 0 to 25% : Very poor rock quality (completely weathered rock)

- 25 to 50% : Poor quality (weathered rocks)

- 51 to 75% : Fair (moderately weathered rocks)

- 76 to 90% : Good (hard rock)

- Above 90% : Excellent (fresh rocks)

This classification gives engineers a quick way to assess the suitability of a rock mass for supporting structures. The higher the RQD, the higher the quality of the rock

Why is RQD Important in Soil Investigation?

The importance of RQD in soil investigation cannot be overstated. When planning any type of construction, it is vital to understand how stable the ground is. RQD provides a reliable indication of rock strength and stability, which is essential for determining whether a site is suitable for development.

For example, in foundation design, engineers need to know whether the rock beneath the structure can bear the load. If the rock quality is poor (low RQD), the structure may settle unevenly, leading to cracks or even collapse. High RQD values suggest that the rock is solid and reliable, reducing the risk of structural failure.

In tunnel construction, knowing the RQD helps engineers decide on the excavation methods and support systems needed. Tunnels built through rock with high RQD values generally require less reinforcement, making the project faster and more cost-effective. In contrast, tunnels in areas with low RQD require additional safety measures, such as steel ribs, shotcrete, or rock bolts.

RQD is also vital for assessing slope stability in road and dam projects. Slopes constructed on weak, fractured rock may be prone to landslides, which can be catastrophic. By measuring the RQD, engineers can evaluate the need for retaining walls or other stabilization techniques.

Additionally, RQD correlates with the permeability of rock, which affects groundwater movement. Fractured rocks with low RQD tend to allow more water to pass through, potentially leading to water seepage problems in underground structures. Hence, understanding RQD is essential not only for stability but also for managing water-related risks.

How is RQD Measured?

The process of measuring RQD begins with core drilling. This involves drilling a vertical or inclined hole into the ground using a rotary core barrel equipped with a diamond-tipped bit. As the drill advances, it extracts a cylindrical core of rock from the subsurface.

Once the core is brought to the surface, it is carefully removed from the barrel and laid out in a core box in the same sequence it was recovered. Each core run is then visually inspected, and only those pieces of rock that are longer than 10 cm and unbroken are measured. These lengths are summed up and divided by the total length of the core run to calculate the RQD percentage.

It is essential that the drilling and core handling processes are performed carefully. Improper techniques can result in core breakage, leading to underestimation of the RQD. Furthermore, the orientation of the borehole relative to existing joint patterns in the rock can also affect the RQD. Drilling parallel to joint sets may yield longer intact pieces, resulting in an artificially high RQD.

While core diameter can influence the accuracy of RQD measurement, the NX-size core (54.7 mm) is commonly used in most investigations. Larger diameters tend to give more reliable results because they reduce the chances of breaking the core during extraction.

Applications of RQD

Dam Design

Dams, especially those built to retain large bodies of water, rely heavily on a watertight foundation. This is usually achieved by anchoring the dam structure onto solid bedrock. However, natural rock formations are rarely uniform or impermeable. They may contain joints, fissures, cavities, and weathered zones that can lead to seepage, a major safety concern in dam construction.

Through borehole investigations, parameters like RQD and Core Recovery (CR) help engineers assess the continuity and soundness of the rock foundation. Low RQD values may indicate the need for extensive grouting to seal voids and reduce permeability. Consequently, RQD not only aids in evaluating rock quality but also informs decisions related to seepage control, foundation treatment, and overall dam stability.

Pile Foundation

In pile foundation design, understanding the rock’s condition is essential. And this is where parameters like Rock Quality Designation RQD and CR come into play. These two indicators provide critical insight into the quality and continuity of the rock strata where piles are to be socketed.

High RQD values indicate competent rock that can support higher loads, while low values may suggest fractured or weathered zones requiring design adjustments.

Tunnel Design

In tunnel engineering, whether the tunnel is lined or unlined, RQD plays a vital role in determining both safety and construction efficiency. For lined tunnels, particularly those reinforced with concrete, the quality of the surrounding rock mass directly influences the structural load assumptions for the tunnel lining. In unlined tunnels, RQD helps assess the self-supporting capacity of the rock post-excavation.

If the RQD indicates poor rock quality, engineers must incorporate additional support systems such as steel ribs, rock bolts, or shotcrete. Furthermore, in zones with weak or heavily fractured rock, grouting is often necessary to improve stability and control water ingress.

Rock Anchoring

Rock anchors are typically used to stabilize retaining walls, gravity structures, or prevent uplift in foundations and slabs. Their performance is highly dependent on the integrity of the rock mass into which they are embedded.

For anchors to mobilize their full design capacity, it often requiring embedment depths of 12 meters or more, the rock must be free of significant voids, fractures, or weak zones. If RQD values reveal poor rock quality, injected grout may escape through cracks and fissures, reducing bond strength and compromising the anchor’s load-carrying ability.

RQD in Malaysia

Malaysia, with its diverse geological settings ranging from granite and limestone to sedimentary and volcanic rock formations, presents a wide spectrum of rock mass qualities.

Rock Quality Designation (RQD) plays a pivotal role in Malaysian infrastructure development, especially for large-scale construction projects such as highways, tunnels, dams, and high-rise buildings.

SMART Tunnel, Kuala Lumpur

A notable example of the importance of RQD in a real project is the SMART Tunnel (Stormwater Management and Road Tunnel) in Kuala Lumpur, Malaysia. This 9.7 km long tunnel serves dual purposes which is, it diverts floodwaters and also functions as a road tunnel during dry periods.

Before construction began, extensive geotechnical investigations were carried out, including RQD measurements along the proposed tunnel alignment. In sections where RQD values were high (above 90%), the tunnel boring machines could operate smoothly with minimal support.

However, in areas where RQD dropped below 50%, additional reinforcements like rock bolts and steel ribs were installed to prevent collapse and ensure worker safety.

Kajang Rock Quarry in Semenyih, Selangor

A study conducted there used seismic refraction in combination with core drilling to assess the subsurface rock quality. The RQD values measured were impressively high: 98.63%, 98.38%, 99.03%, and 96.43% across four locations.

These readings indicated excellent rock quality, ideal for construction with minimal need for reinforcement. The study validated that granite in this area was largely intact and highly suitable for engineering purposes, reducing construction risks and costs.

This aligns with common findings in many granite-dominated regions of Peninsular Malaysia, where the unweathered granitic bedrock typically produces high RQD values.

In contrast, karstic limestone areas, such as those found in the state of Perlis or the Kinta Valley in Perak, often yield lower RQD values. Limestone terrain is well known for its irregular weathering profiles and presence of solution cavities.

During core drilling in these areas, engineers frequently encounter fractured rock, voids, and highly weathered zones. As a result, RQD values can be as low as 30–50%, indicating poor to fair rock quality.

Pahang–Selangor Raw Water Transfer Tunnel

This project required boring through different types of rock, including granite, schist, and metasedimentary formations. The geotechnical report revealed varying RQD values along the 44.6 km alignment.

In granite sections, RQD was generally above 85%, allowing the tunnel boring machines (TBMs) to proceed with minimal disruption. However, schist and weathered zones exhibited RQD values as low as 40–60%, necessitating additional rock support systems like rock bolts, steel ribs, and shotcrete.

Bukit Kukus in Penang

In hilly regions like Bukit Kukus in Penang, slope stability is a major concern. Road construction in these areas requires comprehensive soil and rock investigations. RQD is critical in determining whether the slope rock mass is strong enough to remain stable without expensive retaining structures.

In many such road projects, engineers correlate low RQD values with areas prone to landslides, especially during heavy rainfall. This enables the planning of preventive measures such as slope reinforcement, drainage improvement, and erosion control systems.

Mass Rapid Transit (MRT), Kuala Lumpur

Lastly, in urban infrastructure development such as the Mass Rapid Transit (MRT) projects in Kuala Lumpur, RQD serves as a benchmark for designing underground stations and tunnels. The variable geology beneath the Klang Valley ranging from Kenny Hill Formation (interbedded sandstone and shale) to granitic and limestone bedrock, means that engineers encounter a wide range of RQD values.

In the MRT Sungai Buloh–Kajang (SBK) line, areas with low RQD required modifications to tunneling methods and increased use of ground support systems to ensure the safety of the tunneling process and nearby structures.

Limitations of RQD

Although Rock Quality Designation (RQD) is a widely used and valuable tool in soil investigation, it still got some limitations.

Does Not Take Joint Orientation into Consideration

One of the most significant limitations of RQD is its inability to capture the orientation of joints in the rock mass. While RQD measures the length of intact core pieces, it does not provide any information about the direction or inclination of natural fractures or joints within the rock.

This can be misleading. For example, a core extracted perpendicular to the joint planes might appear solid and give a high RQD value. However, the same rock mass may have frequent, closely spaced joints parallel to the core axis, which will not be evident in the RQD reading.

These joints can critically affect the stability of slopes, tunnels, or foundations, yet remain undetected if RQD is the sole assessment method.

For example, in the highland areas of Genting Highlands, road cut slopes are often constructed in highly jointed granitic rock. In some investigations, borehole cores indicated high RQD values, but actual slope failures occurred post-construction due to unfavorably oriented joints not captured in the core. This demonstrates that relying on RQD alone, without considering joint orientation mapping on exposed faces, can lead to serious misjudgments.

Susceptible to Handling and Drilling Damage

RQD assumes that all breaks in the core are natural. However, in reality, many breaks occur due to improper drilling techniques or rough handling during core extraction, transportation, or logging. These artificial breaks can lower the RQD value, giving the false impression of poor rock quality.

This leads to overly conservative design decisions such as unnecessary reinforcements, over-excavation, or over-designing of foundations all of which can significantly increase project cost and duration.

Inapplicable in Weathered or Soft Rock

RQD works best for hard, intact rock masses. In highly weathered rock or soft rock materials like shale or laterite, even if the rock mass has few natural discontinuities, the core may still break into short pieces due to its low strength. This can result in an RQD of 0%, which inaccurately suggests very poor rock quality when the reality might be different.

Neglects Rock Weathering and Chemical Alteration

Another limitation in RQD is the degree of weathering or chemical alteration of the rock. Rock that is highly weathered may still produce long core pieces and yield a high RQD, even though its strength and durability have been significantly compromised. This can lead to an overestimation of the rock’s ability to support loads or resist erosion and seepage.

For instance, a case in the Klang Valley, granitic rocks often exhibit deep weathering profiles. During a foundation investigation for a multi-storey development in Petaling Jaya, the recovered cores from the upper weathered zones appeared intact and gave RQD values above 75%. However, lab testing later revealed the strength of the rock was severely reduced due to weathering, prompting a revision of the pile foundation design.

Single-Dimensional Assessment

RQD provides a single numerical value to describe rock quality. While this is convenient for quick interpretation, it lacks the multidimensional detail required for complex geological conditions. Factors like joint spacing, aperture, infill material, water conditions, and rock type are equally important but are not represented in the RQD value.

Therefore, RQD should never be used in isolation. It must be supplemented with more comprehensive classification systems such as the Rock Mass Rating (RMR) or Q-system, which consider multiple rock mass parameters.

Enhancements and Alternatives for RQD

While RQD is a useful and widely adopted tool in geotechnical investigations, its limitations have led engineers to seek ways to improve its accuracy or to supplement it with other complementary methods. These enhancements and alternatives help provide a more complete and reliable picture of subsurface conditions, especially in complex geological settings.

Refining the RQD Methodology

To improve the reliability of RQD measurements, engineers often make adjustments based on specific site conditions. For example, they may take into account the orientation of joints in relation to the drilling direction. Drilling perpendicular to the dominant joint set can yield more representative RQD values, while drilling parallel to joints may produce longer core pieces that do not accurately reflect the actual condition of the rock mass.

In highly weathered or weak rock formations, where intact core recovery is difficult, modifications may include the use of larger core diameters (such as HQ or PQ sizes) or more careful drilling techniques to minimize artificial breaks. These efforts help reduce the chances of underestimating RQD due to drilling-induced core damage.

Geophysical Techniques as Non-Invasive Alternatives

In recent years, geophysical methods have gained popularity as non-destructive alternatives or supplements to core-based investigations like RQD. These techniques can assess rock mass quality over larger areas and at deeper depths, with minimal disturbance to the ground.

Some common geophysical methods include:

Seismic Refraction

Measures the travel time of seismic waves to identify changes in subsurface material stiffness and layering. It can indicate zones of fractured or weak rock that may not be captured by isolated boreholes.

Electrical Resistivity Imaging (ERI)

Uses electrical currents to map subsurface resistivity, which correlates with rock saturation, porosity, and fracture zones. It’s particularly useful in detecting water-bearing fractures or soft soil zones.

Spectral Analysis of Surface Waves (SASW)

A technique that analyzes surface wave velocities to estimate the stiffness of subsurface layers. This method is valuable in assessing the mechanical properties of soil and weathered rock without drilling.

These methods are especially useful during the preliminary stages of a project, allowing engineers to narrow down critical zones for detailed investigation, and to cross-verify data obtained from boreholes and RQD measurements.

Rock Mass Classification Systems: RMR and Q-System

To overcome the single-dimensional nature of RQD, engineers frequently rely on more comprehensive rock mass classification systems. Two of the most widely used are:

Rock Mass Rating (RMR) System

Developed by Bieniawski, the RMR system includes RQD as one of its parameters, but also considers factors such as joint spacing, joint condition, groundwater inflow, and rock strength. This multi-factor approach allows for a better overall assessment of rock behavior under load.

Q-System

Introduced by Barton et al., the Q-system also uses RQD in combination with other parameters, such as joint roughness, joint alteration, water conditions, and stress orientation. It is particularly useful in tunnel design and helps determine appropriate support systems based on the overall quality of the rock mass.

These systems not only help engineers classify the rock but also offer guidance on design decisions such as support requirements for underground excavations or the type of foundation system suitable for surface structures.

Conclusion

RQD, or Rock Quality Designation, is a vital tool in the field of geotechnical engineering. It provides a simple yet effective way to evaluate the quality of rock masses, which is crucial for the design and safety of construction projects. From tunnels and bridges to skyscrapers and dams, knowing the RQD helps engineers make informed decisions that save time, money, and lives.

While RQD has its limitations, when used correctly and in conjunction with other methods, it remains one of the most valuable parameters in soil and rock investigation.